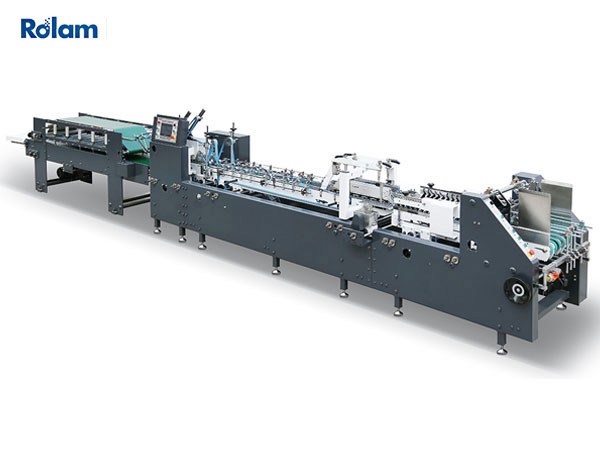

Folder gluer machine product features

1. The sponge belt is used to feed the paper, and the flexible adjustable paper feeding knife is combined with the vibration motor to separate the paper web smoothly and accurately. The clutch-controlled paper feeding system under photoelectric control ensures that the paper webs are accurately fed into the gluing section to achieve non-stop paper feeding.

2. The imported hot melt glue system under photoelectric control can be adjusted according to the size of the paper web and the glueing position to meet the production requirements.

3. The working system of forming section adopts the organic combination of adjustable inner and outer molds controlled by photoelectricity and cylinder to accurately and consistently complete the forming of paper embryos. The inner and outer molds can also be adjusted according to the size of the paper embryo to meet the processing requirements of different sizes of paper boxes.

4. The conveying section is driven by separate speed-regulating motor, which can be adjusted with the production speed of the main machine to ensure the orderly output of the finished paper boxes.

5. Adopt frequency converter to control the motor drive, which is balanced in speed regulation and power saving.

6. Adopt advanced timing belt and timing wheel drive to ensure accurate, stable and low noise transmission.

Folder gluer machine maintenance and care

1 The machinery should be kept clean and should be cleaned frequently.

2 mechanical belt with water to keep clean, anti-stop slipping especially to prevent sticking to the top of the belt. Hook bottom on the glue wheel and glue box must be washed every day after work, otherwise the glue box inside the glue will freeze, affecting the effect of gluing.

3 The glue box of the gluing part of this fold should be kept clean and scrubbed frequently.

4 It is strictly forbidden to adjust the speed when the governor stops, otherwise the belt will be worn very seriously.

5 The inner row of board support, shaft, rods, to often clean, plus lubricant oil and grease mixed with a piece of better effect can be left and right shaking anti-stop rust.

6. Before starting the machine is best to drive slowly, check the machine has no abnormalities.