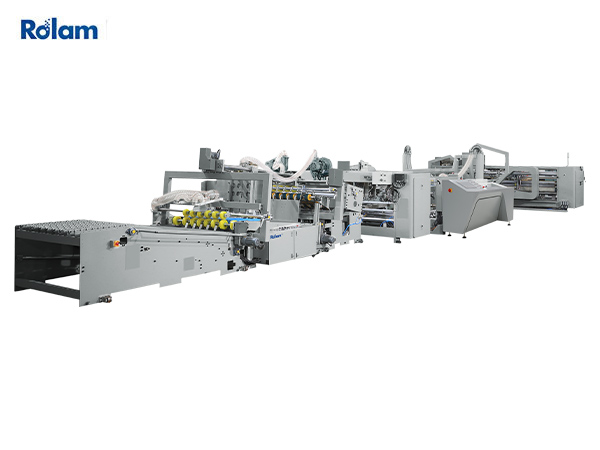

SP SERIES Product Advantages

Each part is independently module tuned and controlled by servo motors.

By connecting with high-precision chains, it can ensure that the screw driven guide plate moves synchronously and smoothly.

New structural design, printing format more in line with the market, environmentally friendly.

Adopting a grouped design concept, each section of the machine has a pedal platform operation port, which facilitates operators to enter the interior of the machine for operation.

The belt bearing guide rail adopts imported brands and carefully designs every subtle structure of the machine.

The fully automatic dual splicing box machine adopts an upper and lower paper output mechanism. The upper paper output mechanism breaks the traditional belt friction force due to the upward printing surface of the cardboard box. For products with high requirements such as laminating film, the paper output is prone to scratching, which is a pain point in the industry. In response to industry pain points, we have innovatively developed a new downward suction Feida paper feeding mechanism.

This mechanism can be installed on existing double splicing machines, with a compact structure that does not take up space, effectively saving the customer's factory space. Moreover, this anti scratch mechanism can quickly switch between use and non use. When the product does not require an anti scratch device, it can be converted to normal paper output mode with just one click back to the origin.

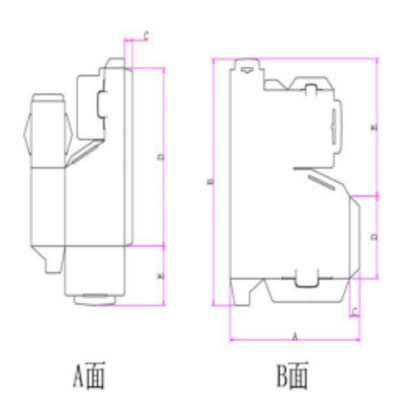

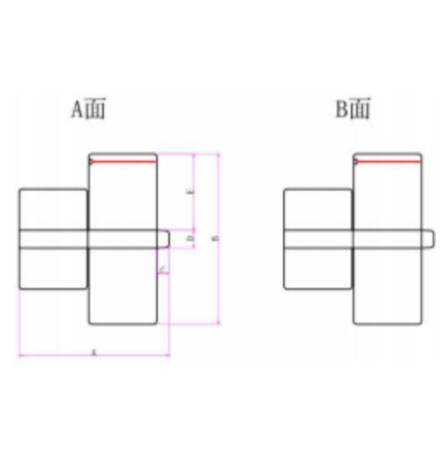

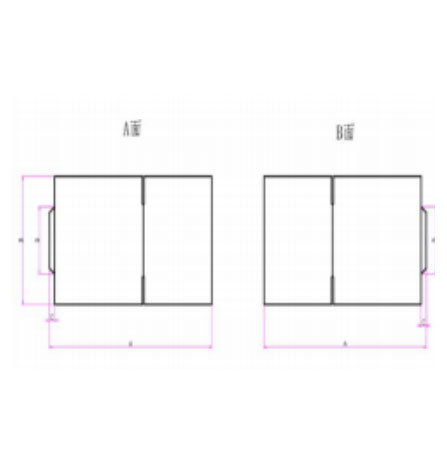

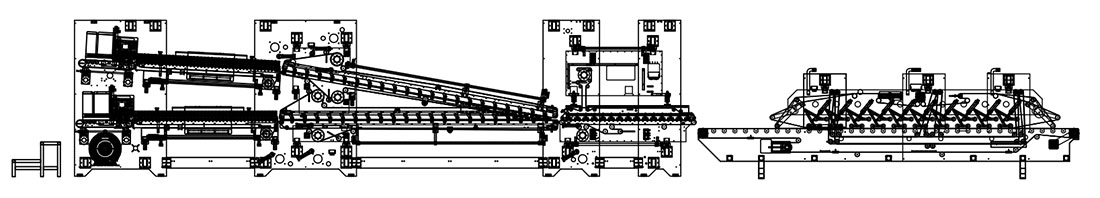

SP SERIES Foundation Drawing

SP SERIES Parameters

|

MODEL |

1650 |

2000 |

2400 |

|

|

Machine configuration |

1.Memory function, one-key adjustment 2.Eight Control 2-gun spraying glue machine 3.One set of hot melt adhesive with two tubes-two guns (6 meters rubber hose) 4.Scratch resistant Feida system 5.Servo positioning, servo folding |

|||

|

Jog Speed |

20m/min |

|||

|

Paper material |

Irregular carton, top and bottom buckle box, irregular box, Flat box |

|||

|

Maximum speed |

160m/min |

|||

|

Folding box thickness |

10mm |

|||

|

Supply voltage |

3P 380V 50HZ |

|||

|

Paper feed width |

500mm-1650mm |

500-2000mm |

500-2400mm |

|

|

Paper feed length |

300mm-1700mm |

300-1700mm |

300-1700mm |

|

|

Length* Width*Height |

15.5*2.95*2.6m |

15.5*3.3*2.6m |

15.5*3.7*2.6m |

|

|

Weight |

22T |

23.5T |

26T |

|

|

Power |

45kw |

50kw |

50kw |

|

SP SERIES Function

● Can produce AB substrate, card, corrugated, flat box, color box, three-layer box, five layer box, seven layer box

Adapt to various irregular shaped boxes AB A.B.C.E.AB.BC.EB.EE.

● Our fully automatic double splicing box machine has an additional front gear gauge, synchronous belt, servo tracking module compared to other brands of machines, which provides precise positioning for the front and rear alignment of the upper and lower cardboard boxes. The characteristic of this mechanism is to follow the direction of the cardboard box's forward movement and run with it, without causing resistance to the box's forward movement or affecting its surface. This is achieved through a complex mechanical structure and program control of

● The machine has a one key adjustment function

● The fully automatic double splicing box machine adopts a servo motor folding mechanism for folding the edge of the paper box. The servo motor drives the cam swing rod through the transmission shaft to fold the edge of the paper box. The folding device is fixed by a linear guide and adjusted by a screw to move the linear guide, which can adapt to different sizes of paste ports

● Each group of machines is supported by thick wall panels, which are 25mm thick high-strength steel

● Using photoelectric counting, it can record the total number or count quantitatively

SP SERIES Samples Parameters

|

Irregular carton Parameter Detail Table |

|||||||

|

Irregular carton |

Parameter |

||||||

|

|

Box width |

480mm-1650mm |

480mm-2000mm |

480mm-2400mm |

|||

|

Box height |

380mm-1500mm |

380mm-2000mm |

380mm-2400mm |

||||

|

Wide living space |

25mm-60mm |

25-60mm |

25-60mm |

||||

|

Long living position |

100mm-1100mm |

100mm-1100mm |

100mm-1100mm |

||||

|

Box lid length |

0mm-500mm |

0mm-500mm |

0mm-500mm |

||||

|

Number of layers |

Products |

Adjustment time |

Speed/min |

Output |

Precision |

||

|

3 layer box adjustment time |

Turnover time |

15-30min |

30-70m/min |

1500-4000/h |

±1 |

||

|

New Product Time |

20-50min |

30-70m/min |

±1 |

||||

|

5 layer box adjustment time |

Turnover time |

15-30min |

30-70m/min |

1500-4000/h |

±1.5 |

||

|

New Product Time |

20-50min |

30-70m/min |

±1.5 |

||||

|

7 layer box adjustment time |

Turnover time |

15-30min |

30-50m/min |

1500-2500h |

±1.5 |

||

|

New Product Time |

20-50min |

30-50m/min |

±1.5 |

||||

|

Flat Box Parameters Detail Table |

|||||||||

|

Flat Box |

Parameter |

||||||||

|

|

Box width |

480mm-1650mm |

480mm-2000mm |

480mm-2400mm |

|||||

|

Box height |

380mm-1500mm |

380mm-2000mm |

380mm-2400mm |

||||||

|

Wide living space |

25mm-60mm |

25-60mm |

25-60mm |

||||||

|

Long living position |

100mm-1100mm |

100mm-1100mm |

100mm-1100mm |

||||||

|

Box lid length |

0mm-500mm |

0mm-500mm |

0mm-500mm |

||||||

|

Number of layers |

Products |

Adjustment time |

speed/min |

Output |

Precision |

||||

|

3 layer box adjustment time |

Turnover time |

15-30min |

40-90m/min |

2000-5000/h |

±1 |

||||

|

New Product Time |

20-50min |

40-90m/min |

±1 |

||||||

|

5 layer box adjustment time |

Turnover time |

15-30min |

40-80m/min |

2000-4000/h |

±1.5 |

||||

|

New Product Time |

20-50min |

40-80m/min |

±1.5 |

||||||

|

7 layer box adjustment time |

Turnover time |

15-30min |

30-60m/min |

1500-2500/h |

±1.5 |

||||

|

New Product Time |

20-50min |

30-60m/min |

±1.5 |

||||||

|

Top and bottom buckle box Parameter Details Table |

||||||||

|

Top and bottom buckle box |

Parameter |

|||||||

|

|

Box width |

480mm-1650mm |

480mm-2000mm |

480mm-2400mm |

||||

|

Box height |

380mm-1500mm |

380mm-2000mm |

380mm-2400mm |

|||||

|

Wide living space |

25mm-60mm |

25-60mm |

25-60mm |

|||||

|

Long living position |

100mm-1100mm |

100mm-1100mm |

100mm-1100mm |

|||||

|

Box lid length |

0mm-500mm |

0mm-500mm |

0mm-500mm |

|||||

|

Number of layers |

Products |

Adjustment time |

speed/min |

Output |

Precision |

|||

|

3 layer box adjustment time |

Turnover time |

15-30min |

40-80m/min |

2000-4000/h |

±1 |

|||

|

New Product Time |

20-50min |

40-80m/min |

±1 |

|||||

|

5 layer box adjustment time |

Turnover time |

15-30min |

40-70m/min |

2000-3500/h |

±1.5 |

|||

|

New Product Time |

20-50min |

40-70m/min |

±1.5 |

|||||

|

7 layer box adjustment time |

Turnover time |

15-30min |

30-50m/min |

1500-2500/h |

±1.5 |

|||

|

New Product Time |

20-50min |

30-50m/min |

±1.5 |

|||||