Introduction

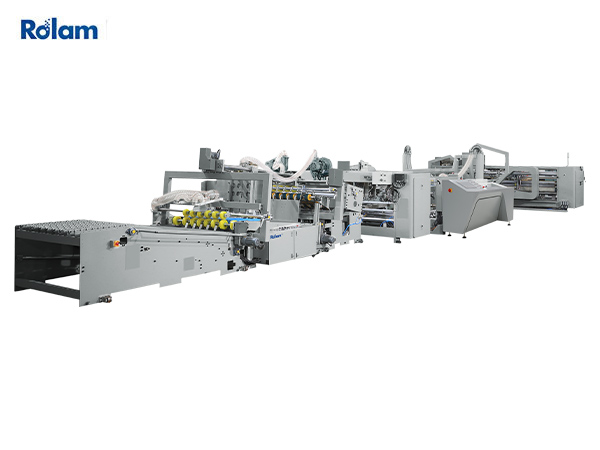

The biggest feature of this machine is its all electric computer operation, which is easy to operate and balances quality and efficiency, saving manpower and material resources. It has two functions: nailing and pasting. Bottom less and covered cardboard boxes can also be nailed; This machine adopts computer screen display operation and fault instructions:

Can store orders and remember 2000 sets of order data; You can complete the order change setting within 3-5 minutes and start mass production; The paper feeding department adopts a leading edge belt type to ensure that the paper feeding rate is not skewed; Each leading edge paper feeding belt can be adjusted separately to increase its height and prolong its service life; There is a side tapping device during paper feeding to ensure neat and smooth paper feeding; The nail head and shaping section are operated by servo motors, ensuring stable and accurate nail spacing The nail head has an additional shaping function, which ensures that the finished product does not produce scissor forks and is neat without beveled edges; The nail head nail speed can reach 1200 nails per minute; It can be nailed with single or double nails, with a maximum nail spacing of 90mm. It can be nailed with reinforced nails, with a maximum nail spacing of 70mm. Taking three nails as an example, it can reach up to 115 nails per minute; The wire delivery adopts a 30 kilogram automatic wire delivery system; Cardboard that can be nailed with three or five layers of A, B, C, and AB waves; The number of needles can be customized and automatically discharged.

Equipment expandable functions:This model can be equipped with a paste head device, which can choose to nail or paste:The paper feeding section can be equipped with an automatic paper feeder; The counting department can be equipped with an automatic packaging machine; Can be equipped with an automatic labeling machine; Can be equipped with an internal adhesive tape machine; Automatic spray system can be added.

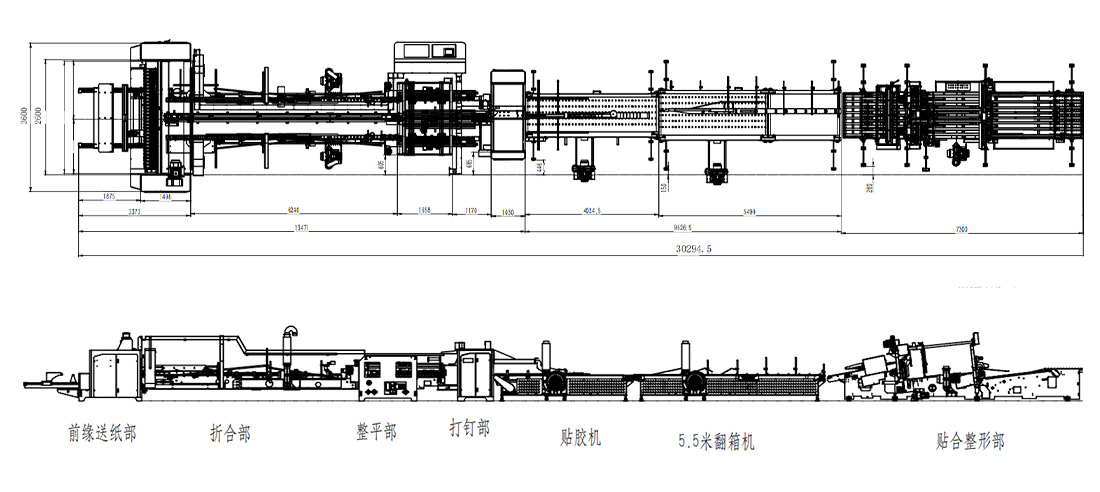

Foundation Drawing

LC-S Parameters

|

Model |

2400 |

2800 |

3200 |

|

Applicable corrugated carton |

3, 5,AB layers of corrugated cardboard |

||

|

Maximum nailing speed |

100 pieces/min (3 nails) |

||

|

90 pieces/min (4 nails) |

|||

|

80 pieces/min (5 nails) |

|||

|

Maximum box gluing speed |

110 pieces/min |

||

|

Reinforcing nail |

30-70mm |

||

|

Head movement pattern |

Fixed nail head |

||

|

Stitching mode |

Two nails / one nail |

||

|

Flat wire is used for driving nails |

Width:1.95mm(±0.05mm) |

||

|

Nail slope |

45° |

||

|

Supply voltage |

3P 380V 50HZ |

||

|

Maximum paper width |

2400 |

2800 |

3200 |

|

Length x width x height |

27x4x2.1m |

27x4.4x2.1m |

27x4.8x2.1m |

|

Net Weight |

16T |

18T |

20T |

|

Total power |

55KW |

55KW |

55KW |

Special Features

This machine uses a computer screen to display operation and fault prompts.

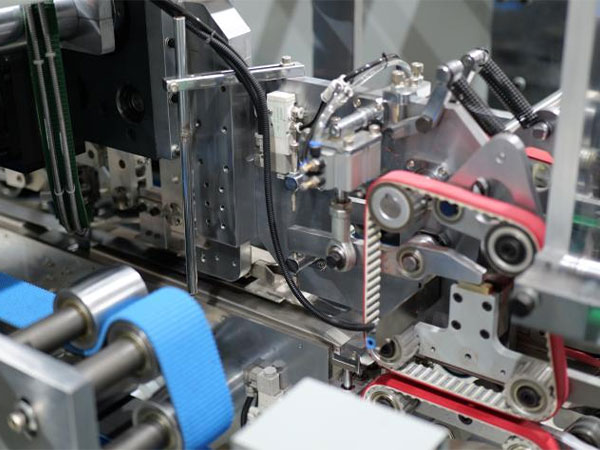

The nail head and shaping part are operated by servo motors, and the nail distance is stable and accurate.

The nail head has an additional shaping function, so the finished product will not produce scissors forks, and it is neat and without bevel edges.

It can also nail boxes without bottoms and lids.

The paper feeding part uses a front edge belt type to feed paper accurately without skewing.

There is a side patting device when feeding paper to make the paper feeding neat and smooth. It can be used for large and small cartons, and can also be connected to an automatic paper feeder.

The size change is operated by computer. The operation screen is located at the main power cabinet. The size can be manually input or called up at the storage order. The size setting of the whole machine can be completed in 3-5 minutes. Each functional size can be positioned with one button (if precise fine-tuning is required, precision fine-tuning can be performed at each functional part), which reduces the operator's machine adjustment time, improves efficiency and ensures the safety of the operator, making large-scale production orders more feasible.

Equipped with remote control operation, the operator can operate more flexibly.

Equipped with centralized lubrication device, which is convenient for refueling.

The paper-gluing and paper-collecting part is equipped with a hollow protective cover to prevent the safety of non-operating personnel.

The whole machine has a fast adjustment speed, and the push plate can be positioned with one button. A skilled operator can debug the machine in just 10 minutes.

The nail head nail speed can reach 1,200 nails per minute.

During high-speed production, for example, with three nails, more than 90 finished products can be produced per minute.

Single nails and double rows of nails can be nailed, with a maximum nail distance of 90 mm.

Reinforced nails can also be nailed, with a maximum nail distance of 65 mm.

Orders can be stored, and 2,000 sets of order data can be memorized.

Three-layer or five-layer cardboard (3-8 mm) can be nailed, A, B, C and AB wave cardboard.

Counting discharge can automatically discharge according to the number of sheets that can be customized.

The nail line specifications used are: 0.68-0.72 X 2.0 (standard nail line specifications of the machine head).

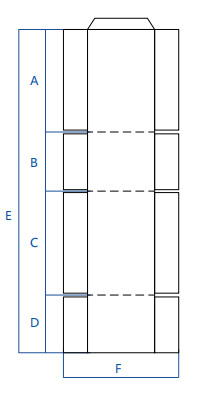

Samples Parameters

| Ordinary box type |  |

|||

|

Model |

2400 |

2800 |

3200 |

|

|

A |

220-600 |

220--700 |

220-800 |

|

|

B |

170-600 |

170-700 |

170-800 |

|

|

C |

220-600 |

220-700 |

220-800 |

|

|

D |

170-600 |

170-700 |

170-800 |

|

|

E |

780-2400 |

780-2800 |

780-3200 |

|

|

F |

295-1350 |

295-1350 |

295-1350 |

|