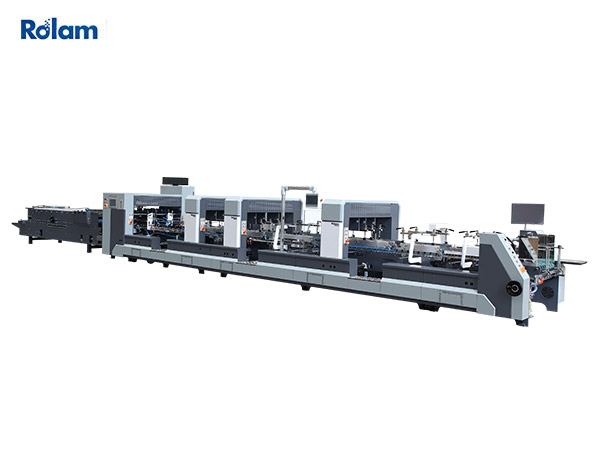

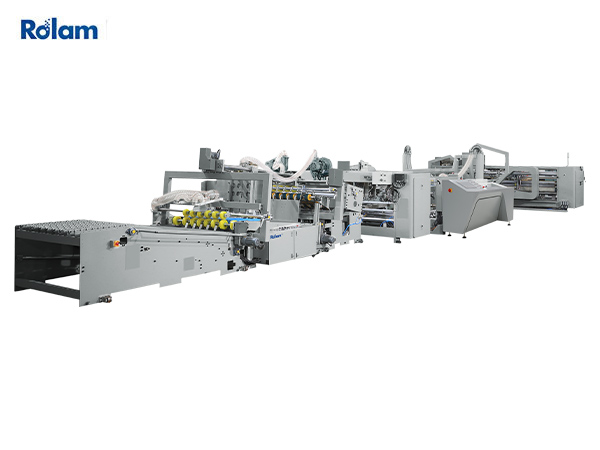

Automatic high speed folding gluing machine is another masterwork of Zhejiang New Luolan Machinery. suitable for straight-line, crash-lock bottom, double wall, 4 & 6-corner boxes.

Intelligent Memory Function Folder Gluer, momory function is an ideal equipment for repeatingdifferent jobs after the first trail with less works . XL-J is suitable for straight-line, double-wall, auto lockbottom, 4 6 corners type folding cartons.

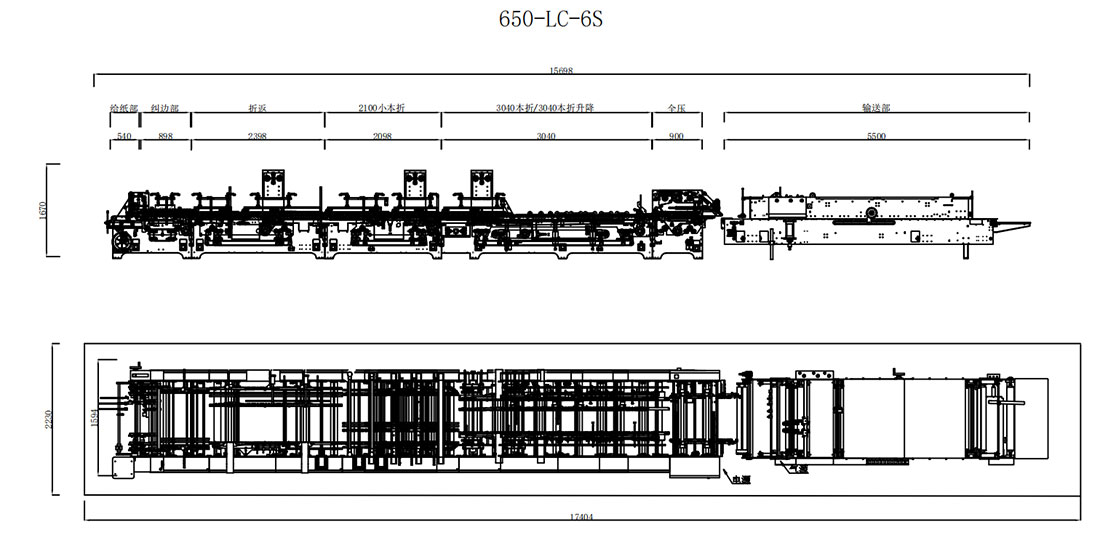

LC-6S Automatic High Speed Folder Gluer Foundation Drawing

LC-6S Automatic High Speed Folder Gluer Technical Parameters

|

MODEL |

650 |

800 |

1100 |

|

Paper material |

Cardboard 210-800gsm, A/B/E Flute |

||

|

Max.Speed |

400m/min |

||

|

Max.thickness of folded box |

12mm |

12mm |

12mm |

|

Way of folding |

Fold 1 and fold 3 are 180°and 135°,fold 2 and fold 4 are 180° |

||

|

Power supply |

3P 380V 50HZ |

||

|

Blank width |

650mm |

800mm |

1100mm |

|

Length x Width x Height |

15.3x1.4x1.6m |

15.6x1.8x1.6m |

15.7x2.2x1.6m |

|

Net Weight |

7.0T |

8.0T |

9.0T |

|

Total power |

30kw |

32kw |

32kw |

LC-6S Automatic High Speed Folder Gluer Function

● Apply to corrugated cardboard paper box.

● Strong stainless steal frame, insure machine running stably with high speed.

● Automatic fault diagnosis alarm function,Wireless remote control for easy user operation.

● Machine with PLC control, photocell touch screen for adjusting machine.

● Low-voltage electrical appliances, button switches, transmission parts, timing belts, press belts, bearings, servo motors, inverters, pneumatic components, etc. are all imported products that meet European and American advanced national safety standards

● Side touch screen displays the machine's speed, output, fault alarm, touch screen controls the machine's start/stop, paper feeding clutch, box receiving part's start/stop, parameter setting and other operations.

LC-6S Automatic High Speed Folder Gluer Product details description

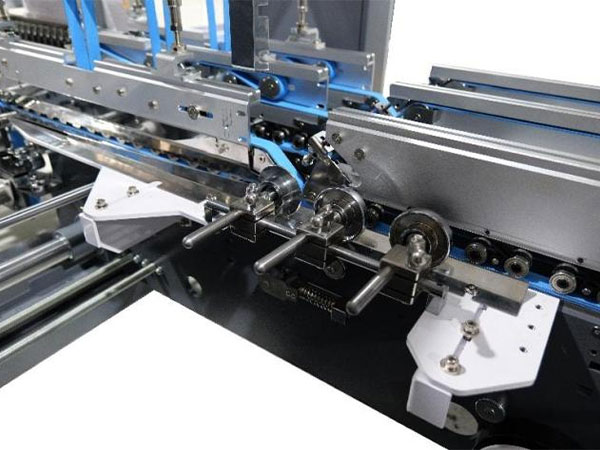

Paper Feeding Section

1.The feed part is driven by variable frequency motor and synchronizes with the main engine

2.Feeder section equipped with three pieces feeding knife, adjust the asymmetrical lengths as per the box sample。

3.Rail width can be horizontally adjusted and set by seven pieces 30mm thickened feeding belt and 10mm metal board.

4.Operators can operate feeder switch in any regional.

5.Embossing drive wheel guide the feeding section belt, side feed gates in the right and left are adjustable according to the products.

6.Vibration device coordinate with motor which helps machine consecutive and automatic feeding quick and simply. Feeder section can stack 400MM height paper board.

Aligner sectionion

The paper board sent from feeder section will be corrected by aligner section to ensure transmission accurately.

Pressing drive pressure can be adjusted up and down to accommodate different paper board thickness.

Pre-folding section

Special first folding line pre-fold 180°. third line 165° ,which perfectly meeting the requirements of automatic packaging industry.

Lower gluing tank

1.Lower gluing tank is 2L.

2.Easy to remove and clean

3.Electronic upper gluing system by guns.

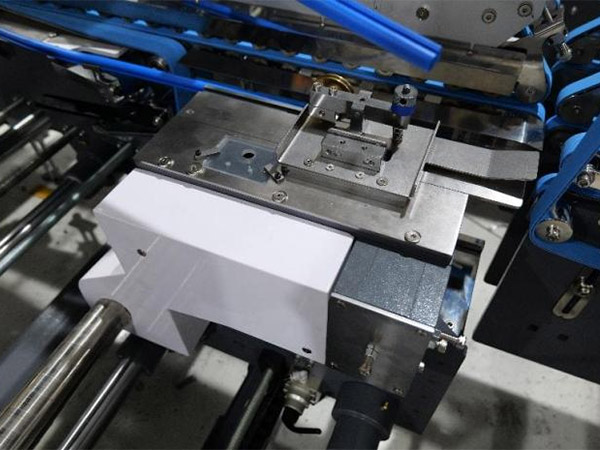

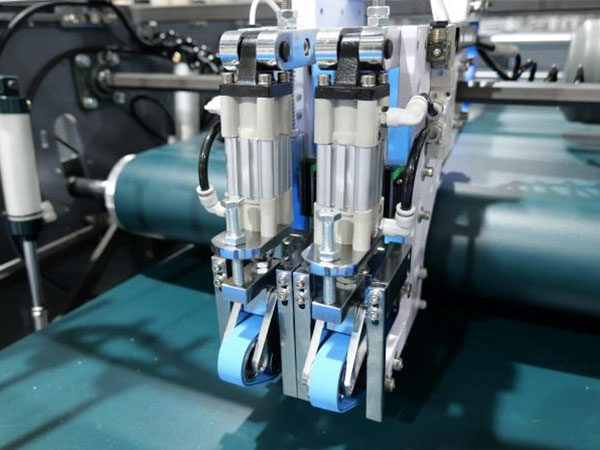

Folding and closing

1.The Second and fourth folding line 180°

2.Folding and closing section transmit from right and left side ,the belt speed can be adjusted separately and correct the way of box running to ensure straightly delivery.

3.Final Folding lower central carrier pnuematicall up and down

Trombone section

1.Up and down belt can be adjusted separately.

2.Equipped with photo electronic counting device and kicking paper device, which can press the paper after accounting and make it easy to pack. Also equipped with feeding paper inspection device.

3.With spanking function for RSC type box

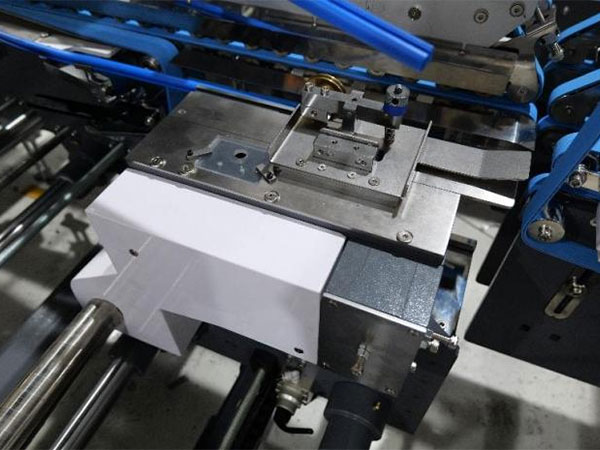

Box Squaring

Full press section continuously and automatically box collection mechanism that ensures a neat transfer to the press section, guaranteeing a well aligned flow.

Transmission

1.Equipped with special additional sponge belt for the press of boxes valley part.

2.Upper section moves back and forward, allowing for different box length.

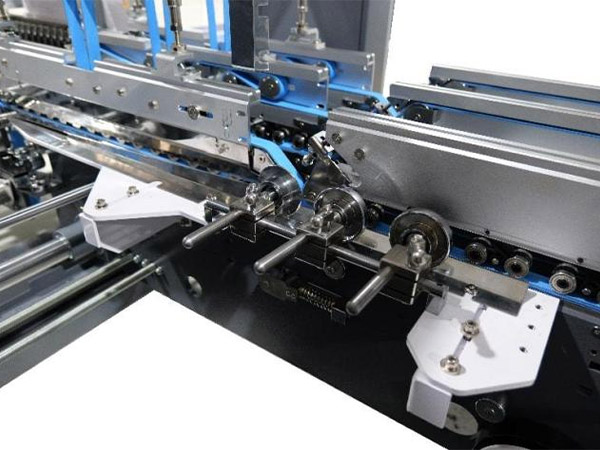

4 /6-corner device

Motorized and untimed electronic back folding system with intelligent servo motor technology

Cold glue system

Equipped with four guns, convenient in the production of 4/6 corner box and various special-shaped box, gluing quickly and accurately sizing.

LC-6S Automatic High Speed Folder Gluer Sample box parameters

|

Straight Line Box |

|

|||

|

Model |

650Type |

800Type |

1100Type |

|

|

Way of folding |

Two carriers |

Two carriers |

Two /three carriers |

|

|

A |

140-650 |

160-800 |

220-1100 |

|

|

B |

70-800 |

70-800 |

70-800 |

|

|

C(min) |

70 |

70 |

70 |

|

|

D |

10-20 |

10-20 |

70-800 |

|

|

E |

65-320 |

75-390 |

105-540 |

|

|

Crash Lock Bottom Box |

|

|||

|

Model |

650Type |

800Type |

1100Type |

|

|

Way of folding |

Two carriers |

Two carriers |

Two /three carriers |

|

|

A |

140-650 |

160-800 |

220-1100 |

|

|

B |

100-800 |

100-800 |

100-800 |

|

|

C(Min) |

70 |

70 |

70 |

|

|

D |

10-20 |

10-20 |

10-20 |

|

|

E |

65-320 |

75-390 |

105-540 |

|

|

H |

30-100 |

30-100 |

30-100 |

|

|

4 Corners Box |

|

|||

|

Model |

650Type |

800Type |

1100Type |

|

|

Way of folding |

Two carriers |

Two carriers |

Two /three carriers |

|

|

A |

160-650 |

160-800 |

160-1100 |

|

|

B |

90 |

90 |

105 |

|

|

H |

70-800 |

70-800 |

70-800 |

|

|

6 Corners Box |

|

|||

|

Model |

650Type |

800 Type |

1100 Type |

|

|

Way of folding |

Two carriers |

Two carriers |

Two/three carriers |

|

|

A |

250-650 |

250-800 |

270-1100 |

|

|

B |

130-800 |

130-800 |

130-800 |

|

|

H |

30-100 |

30-100 |

30-100 |

|