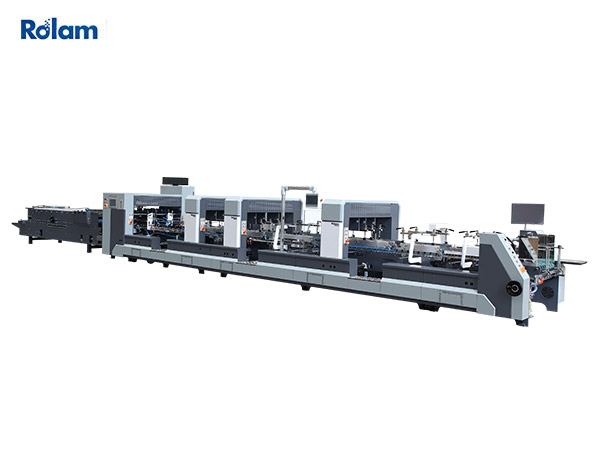

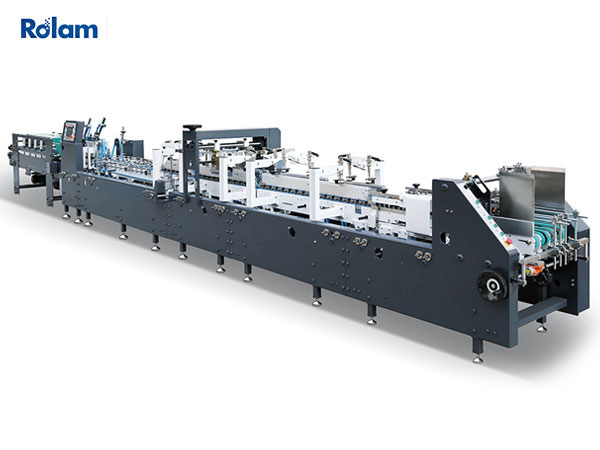

LC-7S Introduction

The LC-7S has undergone continuous research and development, iteration, and is reflected in its precise, fast, and intelligent order switching, multi-functional configuration, including 90 ° rotation, left and right corner belt pre-folding, automatic lifting and lowering of the folding section, and extended crash bottom section and main folding parts. It has V-ribbed belt drives and can produce single line boxes, box in box boxes, crash bottom boxes, and 4/6 corner boxes.

LC-7S is a folder gluer machine that integrates intelligent functions, with a one click adjustment function to achieve automatic board positioning in 5 minutes, creating a competitive advantage for paper box manufacturing.

LC-7S Foundation Drawing

LC-7S Parameters

|

MODEL |

800 |

|

Paper material |

Cardboard 210-800gsm, A/B/ E Flute |

|

Max.Speed |

400m/min |

|

Max.thickness of folded box |

12mm |

|

Way of folding |

180° Fold 1 and fold 3 are 180°and 135°, fold 2 and 4 are 180° |

|

Power supply |

3P 380V 50HZ |

|

Blank width |

800mm |

|

Length x Width x Height |

15.6x1.8x1.6m |

|

Net Weight |

8 T |

|

Total power |

30kw |

XL Parameters

|

|

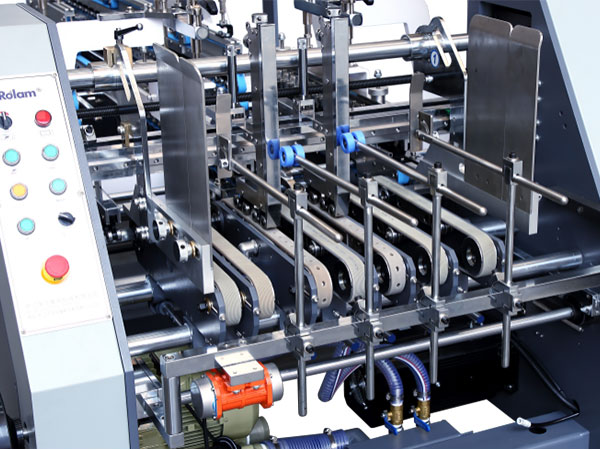

Paper Feeding Section 1.The feed part is driven by variable frequency motor 2.Feeder section equipped with three pieces feeding knife, 3.Rail width can be horizontally adjusted and set by seven 4.Operators can operate feeder switch in any regional. 5.Embossing drive wheel guide the feeding section belt, 6.Vibration device coordinate with motor which helps machine |

|

|

Aligner section 1.The paper board sent from feeder section will be corrected 2.Pressing drive pressure can be adjusted up and down to |

|

|

Pre-folding section Special first folding line pre-fold 180°. third line 165°, |

|

Crash lock bottom section Compete set of crash lock bottom device makes the lock bottom Part perfectly. |

|

|

Lower gluing tank 1.Lower gluing tank is 2Lon the left, easy to remove abd clean. 2.Equipped with KQ spraying system with four controls and three guns. |

|

|

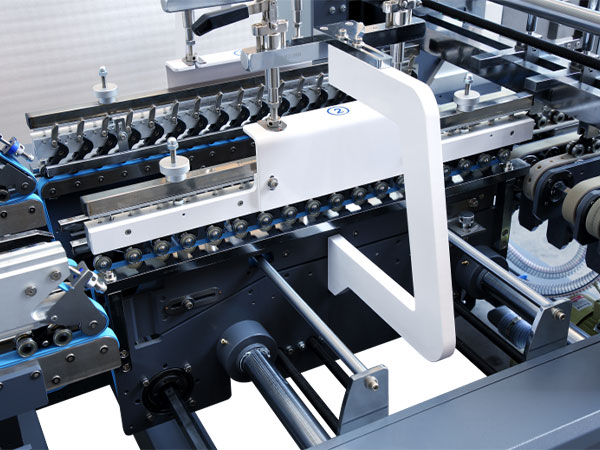

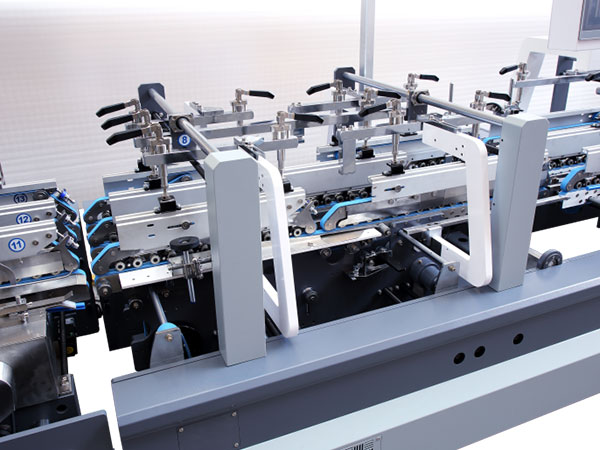

Folding and closing 1.Collapsible central carrier by pneumatic system, saving time for 2.Folding and closing section transmit from right and left side, 3.The main folding part is pneumatically raised and lowered. |

|

|

|

Trombone section 1.Up and down belt can be adjusted separately. 2.Equipped with photo electronic counting device and kicking |

|

|

Transmission Equipped with special additional sponge belt for the press of boxes valley part. Upper section moves back and forward, allowing for different box length. |

|

|

Pneumatic box squaring Full press section continuously and automatically box collection mechanism |

Samples Parameters

| Straight Line Box |  |

|

|

Model |

800Type |

|

|

A |

160-800 |

|

|

B |

70-800 |

|

|

C(Min) |

70 |

|

|

D |

10-20 |

|

|

E |

75-390 |

|

| Crash lock bottom box |  |

|

|

Model |

800Type |

|

|

A |

160-800 |

|

|

B |

100-800 |

|

|

C(Min) |

70 |

|

|

D |

10-20 |

|

|

E |

75-390 |

|

|

H |

30-100 |

|

| 4 Corners Box |  |

|

|

Model |

800Type |

|

|

A |

160-800 |

|

|

B |

130-800 |

|

|

H |

30-100 |

|

| 6 corners box |  |

|

|

Model |

800Type |

|

|

A |

250-800 |

|

|

B |

130-800 |

|

|

H |

30-100 |

|