Safety Operation Regulations of Automatic Folder Gluer

In order to make safe production, improve product quality, reduce production costs, and improve production efficiency, to encourage everyone to develop a good safe working habit, the following rules are specified:

1. Scope of application: all machine operators of the folder gluer

2. Safe operation

1. Make preparations for starting up, and carefully check the parts and safety protection devices for abnormalities before the shift.

Apply the main oil to the parts to be lubricated according to the regulations.

2. Turn on the power supply, check whether the switches of each part are normal, check the protective device of the machine and its

Whether there is any sundries in the peripheral, whether the screw 4 at the fastening part is loose, whether the air supply pressure reaches the working state.

3. The protective device is not allowed to be dismantled randomly. The protective device shall be removed after repairing, and it must be removed during normal production

Must be installed.

4. Do not touch any moving parts when the machine is running.

5. Rotate the slow car to see if the locomotive is running normally. It can only accelerate after normal.

6. In the event of an accident, the scene must be kept and handled by a dedicated person.

Third, the quality requirements of the glue box The quality requirements of the folding box glue mainly include: the glue alignment must be accurate, not heavy. Strong adhesion, no degumming, no inner and outer laps. Does not scratch the printed surface or leave obvious scratches and stains. The box is easy to drop, no lines or corners are broken.

4. In the high-speed operation, complete the paste origami box 1. The various parts must be accurately coordinated,

Cooperate, and the action should be consistent: the folder-gluer machine is longer, and it needs to respond back and forth during work to prevent

Stop accidents.

5. Daily maintenance of equipment

1. The air compressor must drain the accumulated water in the cylinder at the end of the work day (and inspect every shift

Check once the atomized oil in the oil mist cup is not less than?).

2. Click the stop button, after the machine speed is reduced, turn off the machine power.

3. Clean up the machine: items, wipe the machine, the site, and clean and clean. Add moving parts

Oil lubrication.

4. After maintenance, put the tools back to their original places: wipe off the oil to avoid staining the toolbox.

5. Fill in the work report carefully.

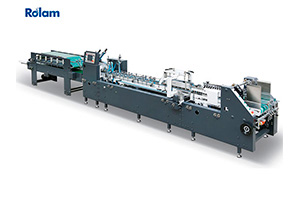

Company Profile

Zhejiang New Luolan Machinery Co., Ltd, whose previous name is Ruian Gaoke Machinery, is established in 2006. As a professional manufacturer, we not only do manufacturing, but also researching, marketing and offering after sales service. We supply quality equipments, effective and convenient solutions for cardboard box and corrugated box folding industry, printing and packaging industry. Gluing folding machine and window patching machine which produced by Zhejiang New Luolan Machinery Co., Ltd have approved by the National Quality Supervision and inspection.