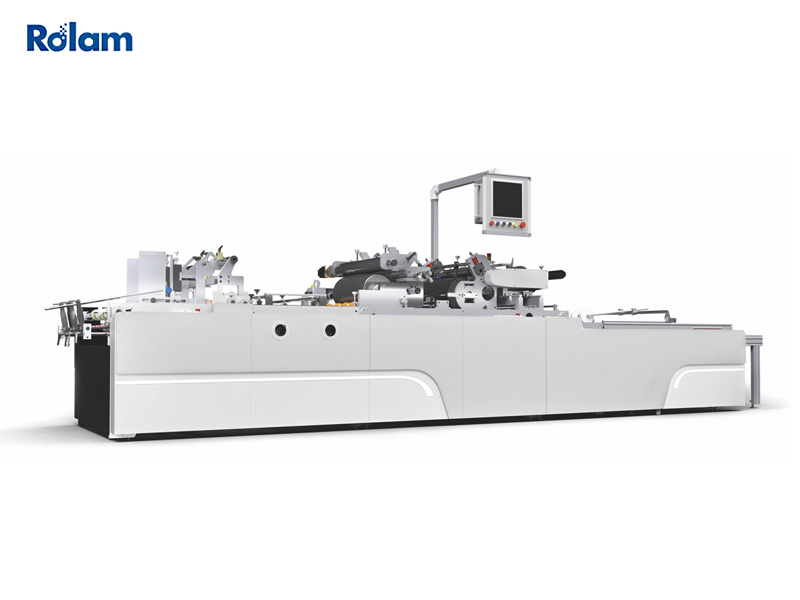

Introduction of the machine:

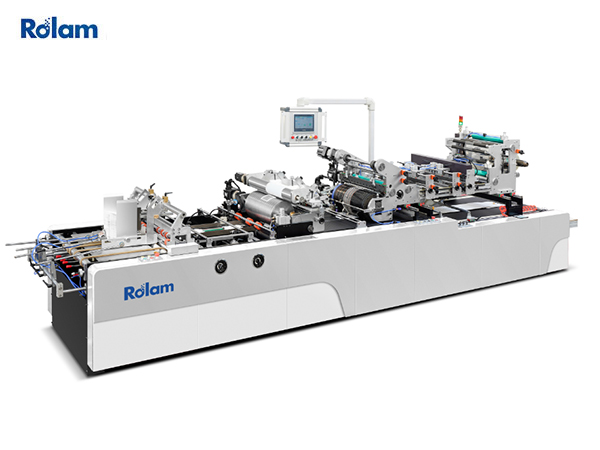

XY-1100-S corner cutting Window Patching Machine is a fully servo machine which is our newly designed these years. The machine widely used in the film patching to be package with or without the window of the wine box, gift box, napkin box, cosmetic box etc. It can also realize the function of the paper gluing ,film patching ,film cutting and paper collection before folding boxes.

The fully servo motor parts included the:

Paper feeder part,chain rail pusher part, the suction belt part, gluing roller part, film suction drum part, the cutting knife part and film feeding part. Add one touch screen to easy control and adjust the machine.

The whole machine adopts intelligent motion control system and man-machine interface. The close cooperation between the servo and the photoelectric sensor enables the deviation of the product to be effectively monitored and corrected at each parts, and finally make the high quality products that customers need.

Parameters

|

MODEL |

XY1100-S |

|

|

Cardboard |

G/㎡ |

200-800gsm |

|

Corrugated paper |

mm |

≤7mm |

|

Max.Working Speed |

PCS/H |

(Corner cutting)5000-10000 (Normal cutting) 4000-12000 |

|

Size of cardboard |

MM |

120x140-780*1100mm |

|

INCH |

4.7x5.51- 30.7x43.3 |

|

|

Size of window |

MM |

60x40 -400x500mm |

|

INCH |

2.36x1.57-15.7x19.6 |

|

|

Film thickness |

MM |

0.05-0.25mm |

|

Power Supply |

KW |

19.5kw |

|

Weight |

KG |

3500kg |

|

Overall Dimensions |

MM |

6.5*2.15*1.95M |

XY1100-S Features introduction

|

|

Paper Feeding Section The paper feeder parts is controller by the servo motor, the paper pile make the intermittent |

|

|

The Pin paper feeding parts The pin paper feeding part adopts servo control, which can be operated directly on the touch |

|

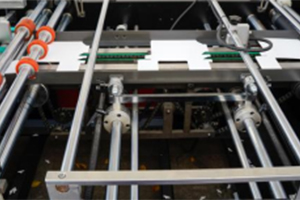

The Suction and conveyor section The suction and conveying part adopts a combination of servo and blower, which |

|

|

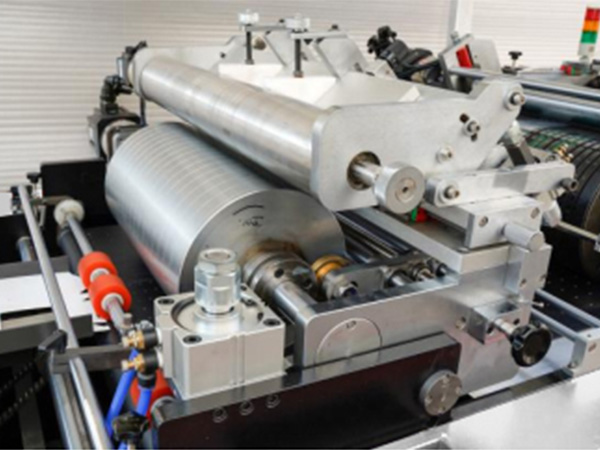

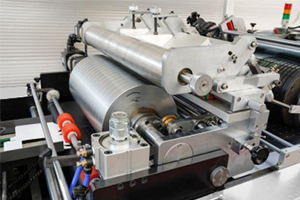

Gluing Section The gluing part is composed of servo motor, cylinder, photoelectric, solenoid valve, Adjustable glue separating guide plate to control the glue range and outflow volume. The gluing roller can freely adjust its position axially and radially without stop the machine. |

|

|

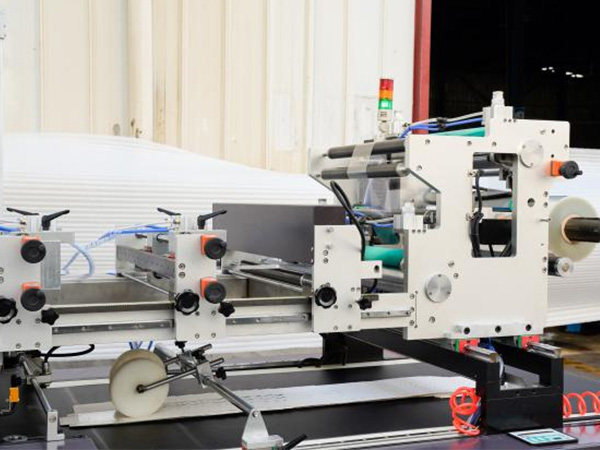

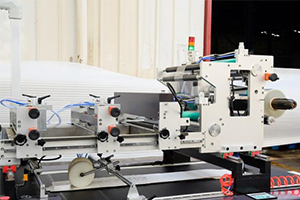

Film cutting, V-Cutting and Creasing Section The film cutting and film with corner cutting and creasing parts are controlled by servo The film mechanism also adopts servo control, which can be jogged as a whole, |

|

|

|

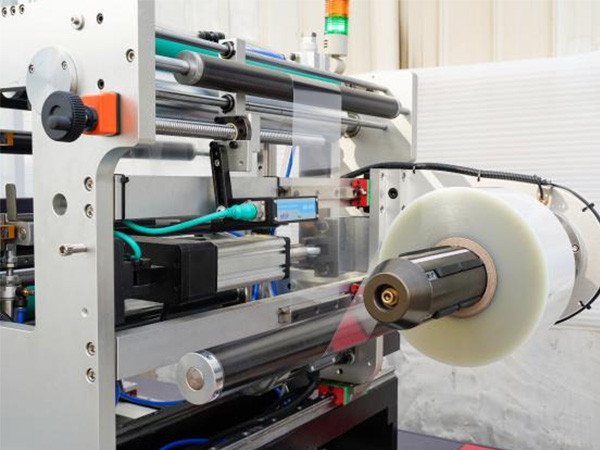

Film cutting, V-Cutting and Creasing Section The film feeding part uses an air expansion shaft to load the film, and automatically corrects the The automatic tension function will always change the tension according to the diameter of the At the same time, it is also equipped with the function of printed film side tracking and stop due |

|

Collecting section The collecting part has the counting function, which can be counted in batches, and has |

|

Servo System Brand: Taiwan DELTA |

|

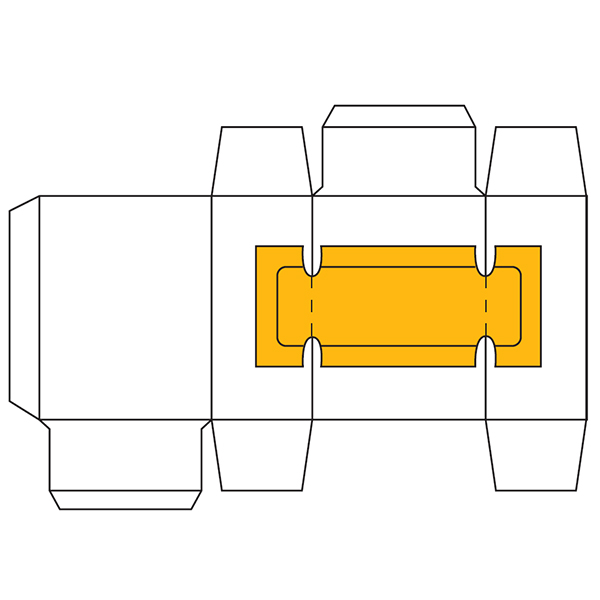

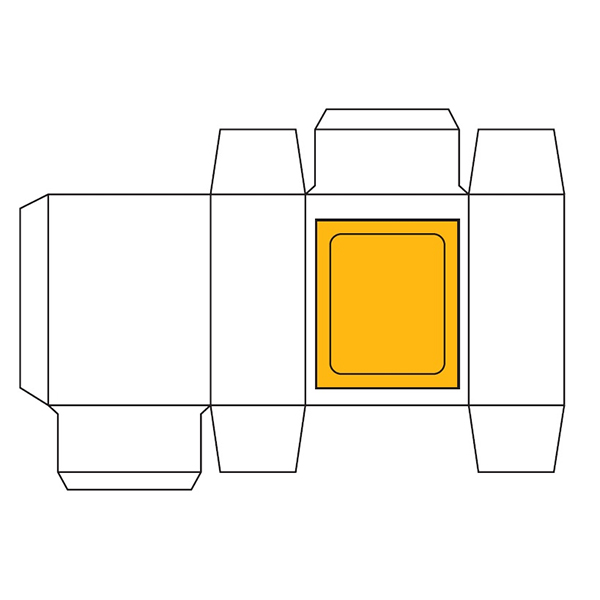

Samples

|

|

|

|

|

|

|

|

|